-

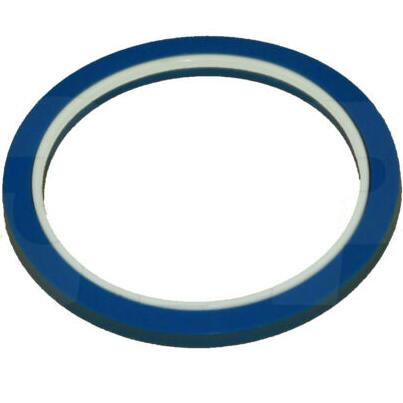

Back up ring 8T8376 Head Seal fits Caterpillar MAT PU UP BACK RING

-

HBY SEAL AS-BUFFER 2892937 – Caterpillar

-

Hydraulic oil seals Wiper seals Dust seals polyurethane PU

-

Wear rings NYLON FIBER GLASS phenolic resin copper powder PTFE

-

Hydraulic oil seals ROD PISTON SEALS PNEUMATIC SEALS

-

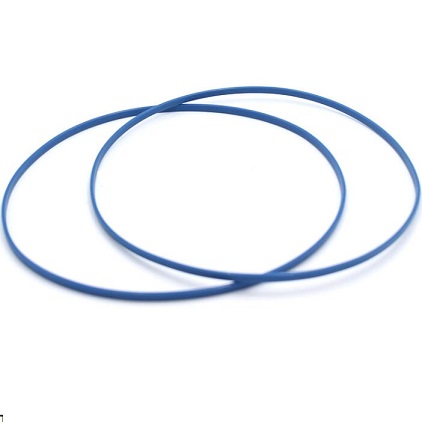

Back up ring polyurethane PTFE gaskets washers

Hydraulic Seals

- 1.Basic concepts of hydraulic seals: Hydraulic oil seal is an important component in the hydraulic system, its function is to prevent liquid leakage and pollution, and ensure the normal operation of the system. The hydraulic oil seal mainly consists of two parts: the oil seal body and the spring. The oil seal body is responsible for sealing, while the spring provides pressure for the oil seal to ensure the sealing effect.

- 2.Material of hydraulic oil seal: The materials of hydraulic oil seals are mainly divided into rubber and plastic. Rubber materials have good sealing and wear resistance, while plastic materials have good chemical corrosion resistance and high temperature resistance. According to the actual application situation, different materials of oil seals can be selected.

- 3.Structure of hydraulic oil seals: The structure of hydraulic oil seals is divided into two types: single lip oil seals and double lip oil seals. Single lip oil seal refers to the oil seal body with only one lip, suitable for low speed and low pressure situations. Double lip oil seal refers to the oil seal body with lip openings on both sides, suitable for high-speed and high-pressure applications.

- 4.Sealing method of hydraulic oil seal" There are two main sealing methods for hydraulic oil seals: contact sealing and non-contact sealing. Contact sealing refers to the presence of certain contact between the oil seal and the shaft, which requires applying a layer of oil film on the oil seal to ensure low friction. Non contact sealing is achieved by a layer of liquid film between the oil seal and the shaft, without the need for an oil film, which can reduce friction and wear.