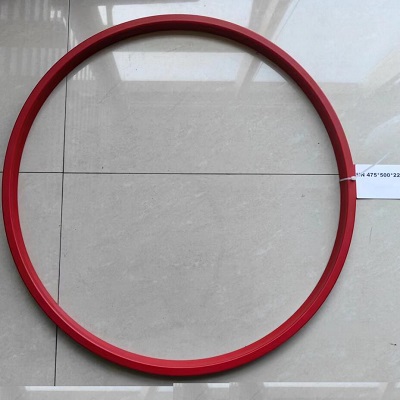

LARGE SIZE UN UHS U CUP SEAL ROD PISTON SEAL 475*500*22 MM RED COLOR Hydraulic Seals

LARGE SIZE UN UHS U CUP SEAL ROD PISTON SEAL 475*500*22 MM RED COLOR Hydraulic Seals

The characteristics of polyurethane seals are summarized as follows:

1. Polyurethane seals have good dust prevention effect. Not easily invaded by external substances, preventing all external interference, and even surface sticky oil and foreign objects can be scraped away;

2. High wear resistance and strong extrusion resistance. Polyurethane seals can move back and forth at a speed of 0.05m/s in a pressure environment of 10MPa without lubrication;

3. Good oil resistance. Polyurethane seals will not corrode even when facing fuel oils such as kerosene and gasoline, or mechanical oils such as hydraulic oil, engine oil, and lubricating oil;

4. Long service life. Under the same conditions, the service life of polyurethane seals is 50 times that of nitrile seals (the table below compares the properties of polyether polyurethane seals with nitrile rubber). From the table below, it can be seen that polyether polyurethane seals have more advantages in wear resistance, strength, and tear resistance.

In addition, it is insulated, soundproof, flame retardant, cold resistant, corrosion-resistant, non absorbent, and easy to install.

For large size polyurethane hydraulic seals are made of imported pipe fittings and milled using mold production technology. So there is no mold limit, just a standard limit. The thin-wall can be changed based on the overall damage situation of the hydraulic cylinder, and the dimensional tolerance can be reasonably arranged. The production and processing are more humanized and suitable for the product. In addition, the hydraulic sealing device made of BD SEALS polyurethane material is not easily deformed and has excellent sealing performance.

1. Sealing performance. PU material hydraulic seal has excellent anti fouling effect and is not easily invaded by external objects, avoiding external influences. Even if there is dirt on the surface, it can be scraped off

2. Grinding characteristics. Wear resistance and strong extrusion resistance. Polyurethane hydraulic seals can move back and forth at a speed of 0.05m/s without wetting in a natural environment of 10MPa water and pressure;

3. Excellent wear resistance, polyurethane materials even when used in gasoline. Lightweight fuel oil or gear oil, automotive oil, mechanical lubricants such as automotive oil and grease will not be corroded;

4. Long term effectiveness. Under the same standard state, the hydraulic sealing life of polyurethane material is 50 times that of nitrile based material. (Below is the comparison of water pressure sealing and NBR performance of methacrylate polyurethane material.) From the following situation, it can be seen that methacrylate polyurethane material hydraulic seals have significant advantages in wear resistance, compressive strength, and rebound.