How are the o-ring cord made or what is the oring cord Manufacturing Process ?

today we will tell you oring cord or rubber cords Manufacturing Process.

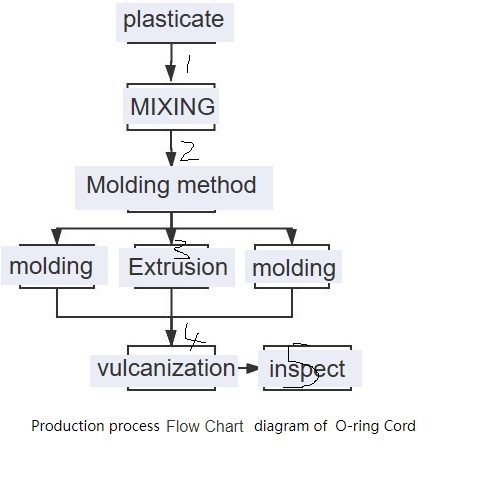

The processing process of rubber sealing strips usually includes the following steps:

- 1. Mixing of rubber raw materials: Firstly, it is necessary to mix the rubber raw materials with processing aids, and then pre-treat them through a high-speed mixer to make them in a highly plastic state.

- 2. Rolling and extrusion: Put the mixed rubber raw materials into a rolling machine or extruder for molding. In this step, it is necessary to control the shape and size of the sealing strip by controlling factors such as pressure and temperature according to the requirements of the sealing strip.

- 3. Cutting and assembly: According to the customer’s needs, cut the formed rubber sealing strip to a certain length and then assemble it. Some sealing strips require joint processing to facilitate processing into longer sealing strips.

- 4. Product testing: Qualified sealing strips need to be inspected to ensure good weather resistance, wear resistance, and sealing performance.

- 5.the o-ring cords manufacturing Process is the similar with o-rings .

It should be noted that the processing technology and process of different types of rubber sealing strips are slightly different. For example, silicone sealing strips typically require a higher processing temperature and longer time to form a special structure of the rubber material to meet the special requirements of silicone sealing strips such as high pressure resistance and high temperature resistance.

In addition, some special shaped sealing strips will be molded using molds, such as rubber U-shaped sealing strips, Z-shaped sealing strips, etc.

Overall, the processing process of rubber sealing strips requires scientific and rigorous process control and inspection standards to ensure that the products meet various customer requirements and relevant national standards. In the production management of sealing strip processing plants, the updating and upgrading of production equipment and processes, strict quality control, gradual improvement of process technology, and high-quality service focused on customer needs are all crucial factors.

Post time: Sep-08-2023