What is a wear ring for and what is the material for a wear ring seal ?

Wear rings should always be installed on the lubrication (wet) side of the seal for best performance. For rod seal , the wear ring should be on the pressure side of the rod seal. For pistons seal , if only one bearing is to be used,

it should be on the side of the piston opposite the rod. This arrangement keeps the piston wear ring further.

Guidance function, mainly applicable to the guidance of hydraulic cylinders, pistons and piston rings in cylinders, playing a supporting and guiding role

The guide ring mainly serves as a guide and is mainly suitable for guiding the pistons and piston rings in hydraulic cylinders and cylinders, playing a supporting and guiding role

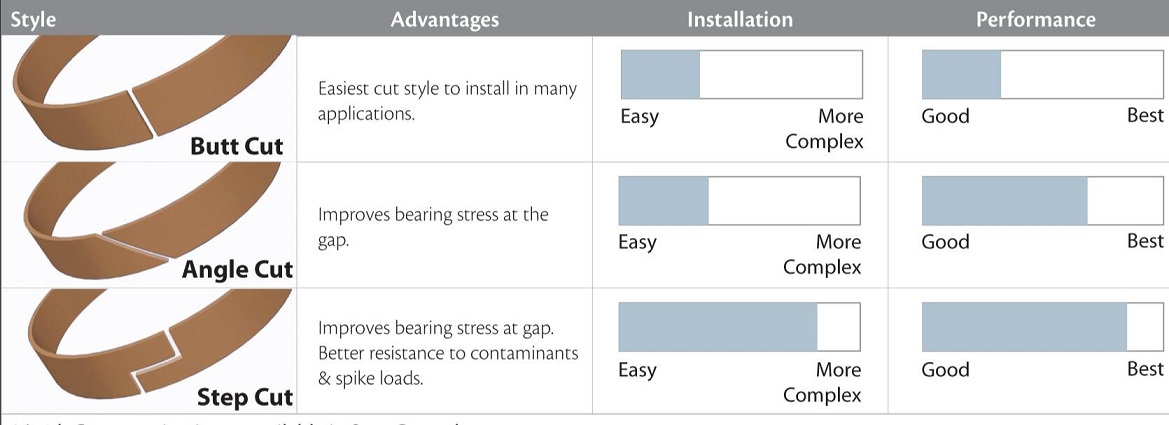

the wear ring cutting way as following :

Guide ring, guide sleeve, support ring, retainer ring, L-retainer ring, phenolic cloth guide ring, bakelite electric ring, washer, guide belt

A guide ring, also known as a support ring, is a component used on the piston or piston rod of a hydraulic cylinder or cylinder to support the movement of the piston or piston rod. It can prevent direct contact and friction between the piston or piston rod and the cylinder body during movement, and plays a role in protecting the cylinder body from damage to the piston or piston rod. The commonly used material for the wear ring (guide ring )is PHENOLIC RESIN , PTFE + COPPER POWDER , NYLON+GLAFIBRE ,POM , Imported woven synthetic resin and more !

Phenolic plastic is a hard and brittle thermosetting plastic commonly known as bakelite powder. It has high mechanical strength, toughness, wear resistance, stable size, corrosion resistance, and excellent electrical insulation performance Suitable for making insulation mechanism components for electrical appliances and instruments, with formability under humid and hot conditions

1. The formability is good, but the shrinkage and directionality are generally greater than those of amino plastics, and they contain volatile substances of water. Preheating should be done before molding, and exhaust should be discharged during the molding process. If not preheated, the mold temperature and molding pressure should be increased

2. The mold temperature has a significant impact on fluidity, and generally when it exceeds 160 degrees, the fluidity will rapidly decrease

3. The hardening speed is generally slower than that of amino plastics, and the heat released during hardening is greater. The internal temperature of large thick walled plastic parts is easily too high, which can lead to uneven hardening and overheating Electric wood guide ring: mainly used for guiding purposes

Wear resistant tape:

Applicable working conditions: Suitable for guiding hydraulic cylinders, pistons and piston rings in cylinders, serving as a support and guide.

Reciprocating speed: ≤ 15M/S Operating temperature: -60 ℃~+220 ℃ Material: PTFE.

Guide ring:

Applicable working conditions: dual use of hole and shaft, supporting and guiding the piston or piston rod.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

L-shaped guide ring:

Applicable working conditions: professional piston, supporting and guiding the piston.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

T-shaped guide ring:

Applicable working conditions: professional piston, supporting and guiding the piston.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

Guide sleeve FI:

Applicable working conditions: professional piston, supporting and guiding the piston.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

Guide sleeve FA:

Applicable working conditions: professional piston, supporting and guiding the piston.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

Guide sleeve FAI:

Applicable working conditions: The piston is professional, providing support and guidance for the piston, and also has a dustproof function.

Usage temperature: -60 ℃~+220 ℃ Material: PTFE, POM, PA.

Glossary of Entries.

The profile wear ring is open and therefore lend themselves to easy assembly .they are extraordinarily wear -resistance and suitable for piston and rod guiding .

the use of these wear ring simplifies the design of pistons and the cylinder heads.

Technical paremeter :

working temperature :-35-150℃

Surface speed: ≤0.5m/s

the size of wear ring as following :

| 40×35×5.5 | Phenolic fabric | |

| 40×35×7.9 | Phenolic fabric | |

| 40×35×9.5 | Phenolic fabric | |

| 40×35×14.8 | Phenolic fabric | |

| 45×40×5.5 | Phenolic fabric | |

| 45×40×7.9 | Phenolic fabric | |

| 45×40×9.5 | Phenolic fabric | |

| 45×40×14.8 | Phenolic fabric | |

| 50×45×5.5 | Phenolic fabric | |

| 50×45×7.9 | Phenolic fabric | |

| 50×45×9.5 | Phenolic fabric | |

| 50×45×14.8 | Phenolic fabric | |

| 55×50×5.5 | Phenolic fabric | |

| 55×50×7.9 | Phenolic fabric | |

| 55×50×9.5 | Phenolic fabric | |

| 55×50×14.8 | Phenolic fabric | |

| 60×55×5.5 | Phenolic fabric | |

| 60×55×7.9 | Phenolic fabric | |

| 60×55×9.5 | Phenolic fabric | |

| 60×55×14.8 | Phenolic fabric | |

| 63×58×5.5 | Phenolic fabric | |

| 63×58×7.9 | Phenolic fabric | |

| 63×58×9.5 | Phenolic fabric | |

| 63×58×14.8 | Phenolic fabric | |

| 65×60×5.5 | Phenolic fabric | |

| 65×60×7.9 | Phenolic fabric | |

| 65×60×9.5 | Phenolic fabric | |

| 65×60×14.8 | Phenolic fabric | |

| 70×65×5.5 | Phenolic fabric | |

| 70×65×7.9 | Phenolic fabric | |

| 70×65×9.5 | Phenolic fabric | |

| 70×65×14.8 | Phenolic fabric | |

| 70×65×20 | Phenolic fabric | |

| 70×65×25 | Phenolic fabric | |

| 70×65×30 | Phenolic fabric | |

| 75×70×5.5 | Phenolic fabric | |

| 75×70×7.9 | Phenolic fabric | |

| 75×70×9.5 | Phenolic fabric | |

| 135×130×9.5 | Phenolic fabric | |

| 135×130×14.8 | Phenolic fabric | |

| 135×130×20 | Phenolic fabric | |

| 135×130×25 | Phenolic fabric | |

| 135×130×30 | Phenolic fabric | |

| 140×135×7.9 | Phenolic fabric | |

| 140×135×9.5 | Phenolic fabric | |

| 140×135×14.8 | Phenolic fabric | |

| 140×135×20 | Phenolic fabric | |

| 140×135×25 | Phenolic fabric | |

| 140×135×30 | Phenolic fabric | |

| 145×140×7.9 | Phenolic fabric | |

| 145×130×9.5 | Phenolic fabric | |

| 145×130×14.8 | Phenolic fabric | |

| 145×130×20 | Phenolic fabric | |

| 145×130×25 | Phenolic fabric | |

| 145×130×30 | Phenolic fabric | |

| 150×145×7.9 | Phenolic fabric | |

| 150×145×9.5 | Phenolic fabric | |

| 150×145×14.8 | Phenolic fabric | |

| 150×145×20 | Phenolic fabric | |

| 150×145×25 | Phenolic fabric | |

| 150×145×30 | Phenolic fabric | |

| 155×150×7.9 | Phenolic fabric | |

| 155×150×9.5 | Phenolic fabric | |

| 155×150×14.8 | Phenolic fabric | |

| 155×150×20 | Phenolic fabric | |

| 155×150×25 | Phenolic fabric | |

| 155×150×30 | Phenolic fabric | |

| 160×155×7.9 | Phenolic fabric | |

| 160×155×9.5 | Phenolic fabric | |

| 160×155×14.8 | Phenolic fabric | |

| 160×155×20 | Phenolic fabric | |

| 160×155×25 | Phenolic fabric | |

| 160×155×30 | Phenolic fabric | |

| 165×160×7.9 | Phenolic fabric | |

| 75×70×14.8 | Phenolic fabric | |

| 75×70×20 | Phenolic fabric | |

| 75×70×25 | Phenolic fabric | |

| 75×70×30 | Phenolic fabric | |

| 80×75×5.5 | Phenolic fabric | |

| 80×75×7.9 | Phenolic fabric | |

| 80×75×9.5 | Phenolic fabric | |

| 80×75×14.8 | Phenolic fabric | |

| 80×75×20 | Phenolic fabric | |

| 80×75×25 | Phenolic fabric | |

| 80×75×30 | Phenolic fabric | |

| 85×80×5.5 | Phenolic fabric | |

| 85×80×7.9 | Phenolic fabric | |

| 85×80×9.5 | Phenolic fabric | |

| 85×80×14.8 | Phenolic fabric | |

| 85×80×20 | Phenolic fabric | |

| 85×80×25 | Phenolic fabric | |

| 85×80×30 | Phenolic fabric | |

| 90×85×5.5 | Phenolic fabric | |

| 90×85×7.9 | Phenolic fabric | |

| 90×85×9.5 | Phenolic fabric | |

| 90×85×14.8 | Phenolic fabric | |

| 90×85×20 | Phenolic fabric | |

| 90×85×25 | Phenolic fabric | |

| 90×85×30 | Phenolic fabric | |

| 95×90×5.5 | Phenolic fabric | |

| 95×90×7.9 | Phenolic fabric | |

| 95×90×9.5 | Phenolic fabric | |

| 95×90×14.8 | Phenolic fabric | |

| 95×90×20 | Phenolic fabric | |

| 95×90×25 | Phenolic fabric | |

| 95×90×30 | Phenolic fabric | |

| 100×95×5.5 | Phenolic fabric | |

| 100×95×7.9 | Phenolic fabric | |

| 100×95×9.5 | Phenolic fabric | |

| 100×95×14.8 | Phenolic fabric | |

| 100×95×20 | Phenolic fabric | |

| 100×95×25 | Phenolic fabric | |

| 165×160×9.5 | Phenolic fabric | |

| 165×160×14.8 | Phenolic fabric | |

| 165×160×20 | Phenolic fabric | |

| 165×160×25 | Phenolic fabric | |

| 165×160×30 | Phenolic fabric | |

| 170×165×7.9 | Phenolic fabric | |

| 170×165×9.5 | Phenolic fabric | |

| 170×165×14.8 | Phenolic fabric | |

| 170×165×20 | Phenolic fabric | |

| 170×165×25 | Phenolic fabric | |

| 170×165×30 | Phenolic fabric | |

| 175×170×7.9 | Phenolic fabric | |

| 175×170×9.5 | Phenolic fabric | |

| 175×170×14.8 | Phenolic fabric | |

| 175×170×20 | Phenolic fabric | |

| 175×170×25 | Phenolic fabric | |

| 175×170×30 | Phenolic fabric | |

| 180×175×7.9 | Phenolic fabric | |

| 180×175×9.5 | Phenolic fabric | |

| 180×175×14.8 | Phenolic fabric | |

| 180×175×20 | Phenolic fabric | |

| 180×175×25 | Phenolic fabric | |

| 180×185×30 | Phenolic fabric | |

| 185×180×7.9 | Phenolic fabric | |

| 185×180×9.5 | Phenolic fabric | |

| 185×180×14.8 | Phenolic fabric | |

| 185×180×20 | Phenolic fabric | |

| 185×180×25 | Phenolic fabric | |

| 185×180×30 | Phenolic fabric | |

| 190×185×7.9 | Phenolic fabric | |

| 190×185×9.5 | Phenolic fabric | |

| 190×185×14.8 | Phenolic fabric | |

| 190×185×20 | Phenolic fabric | |

| 190×185×25 | Phenolic fabric | |

| 190×185×30 | Phenolic fabric | |

| 195×190×7.9 | Phenolic fabric | |

| 100×95×30 | Phenolic fabric | |

| 105×100×7.9 | Phenolic fabric | |

| 105×100×9.5 | Phenolic fabric | |

| 105×100×14.8 | Phenolic fabric | |

| 105×100×20 | Phenolic fabric | |

| 105×100×25 | Phenolic fabric | |

| 105×100×30 | Phenolic fabric | |

| 110×105×7.9 | Phenolic fabric | |

| 110×105×9.5 | Phenolic fabric | |

| 110×105×14.8 | Phenolic fabric | |

| 110×105×20 | Phenolic fabric | |

| 110×105×25 | Phenolic fabric | |

| 110×105×30 | Phenolic fabric | |

| 115×110×7.9 | Phenolic fabric | |

| 115×110×9.5 | Phenolic fabric | |

| 115×110×14.8 | Phenolic fabric | |

| 115×110×20 | Phenolic fabric | |

| 115×110×25 | Phenolic fabric | |

| 115×110×30 | Phenolic fabric | |

| 120×115×7.9 | Phenolic fabric | |

| 120×115×9.5 | Phenolic fabric | |

| 120×115×14.8 | Phenolic fabric | |

| 120×115×20 | Phenolic fabric | |

| 120×115×25 | Phenolic fabric | |

| 120×115×30 | Phenolic fabric | |

| 125×120×7.9 | Phenolic fabric | |

| 125×120×9.5 | Phenolic fabric | |

| 125×120×14.8 | Phenolic fabric | |

| 125×120×20 | Phenolic fabric | |

| 125×120×25 | Phenolic fabric | |

| 125×120×30 | Phenolic fabric | |

| 130×125×7.9 | Phenolic fabric | |

| 130×125×9.5 | Phenolic fabric | |

| 130×125×14.8 | Phenolic fabric | |

| 130×125×20 | Phenolic fabric | |

| 130×125×25 | Phenolic fabric | |

| 130×125×30 | Phenolic fabric | |

| 135×130×7.9 | Phenolic fabric | |

| 195×190×9.5 | Phenolic fabric | |

| 195×190×14.8 | Phenolic fabric | |

| 195×190×20 | Phenolic fabric | |

| 195×190×25 | Phenolic fabric | |

| 195×190×30 | Phenolic fabric | |

| 200×195×7.9 | Phenolic fabric | |

| 200×195×9.5 | Phenolic fabric | |

| 200×195×14.8 | Phenolic fabric | |

| 200×195×20 | Phenolic fabric | |

| 200×195×25 | Phenolic fabric | |

| 200×195×30 | Phenolic fabric | |

| 205×200×7.9 | Phenolic fabric | |

| 205×200×9.5 | Phenolic fabric | |

| 205×200×14.8 | Phenolic fabric | |

| 205×200×20 | Phenolic fabric | |

| 205×200×25 | Phenolic fabric | |

| 205×200×30 | Phenolic fabric | |

| 210×205×7.9 | Phenolic fabric | |

| 210×205×9.5 | Phenolic fabric | |

| 210×205×14.8 | Phenolic fabric | |

| 210×205×20 | Phenolic fabric | |

| 210×205×25 | Phenolic fabric | |

| 210×205×30 | Phenolic fabric | |

| 215×210×7.9 | Phenolic fabric | |

| 215×210×9.5 | Phenolic fabric | |

| 215×210×14.8 | Phenolic fabric | |

| 215×210×20 | Phenolic fabric | |

| 215×210×25 | Phenolic fabric | |

| 215×210×30 | Phenolic fabric | |

| 220×215×7.9 | Phenolic fabric | |

| 220×215×9.5 | Phenolic fabric | |

| 220×215×14.8 | Phenolic fabric | |

| 220×215×20 | Phenolic fabric | |

| 220×215×25 | Phenolic fabric | |

| 220×215×30 | Phenolic fabric |

the install for wear ring seal

Post time: Sep-14-2023