-

Introduction to the Most Comprehensive Oil Seal Knowledge

Introduction to the Most Comprehensive Oil Seal Knowledge. Oil seal is a mechanical component used for sealing, also known as a rotating shaft lip seal ring. The friction part of the machinery is protected from oil entering during operation, and oil seals are used to prevent oil leakage from the...Read more -

Is there a difference between TC, TB, TCY, and SC oil seal ?

Is there a difference between TC, TB, TCY, and SC oil seal ? Oil seal is a device used in various mechanical equipment to prevent oil leakage and dust intrusion. They are usually composed of a metal skeleton and a rubber lip tightly attached to the shaft. There are various types of oil seals, an...Read more -

PS-SEAL PTFE Rotating Shaft Seals

PS-SEAL PTFE Rotating Shaft Seals give you best-in-class sealing performance for a wide range of high-speed and extreme pressure condition. Where others OIL SEAL fail, PS-SEALS (PTFE SEAL) reliably seal rotating shafts at high circumferential speeds, high pressures, and extreme temperatures. P...Read more -

what is the Spring Seal/Spring Energized Seal/Variseal ?

Spring Seal/Spring Energized Seal/Variseal is a high-performance sealing element with a U-shaped Teflon inner special spring. By applying appropriate spring force and system fluid pressure, the sealing lip (face) is pushed out and gently pressed against the metal surface being sealed to generate ...Read more -

Floating oil seal features

Floating oil seal is a common name for floating seals, belonging to a type of mechanical seal in dynamic seals. It has excellent sealing performance in harsh working environments such as coal powder, sediment, and water vapor. It is a compact mechanical seal mainly used in low speed and heavy loa...Read more -

Comprehensive guide for selecting high-quality oil seals

When selecting oil seals, it is necessary to have a clear understanding of their role in preventing leaks and ensuring smooth mechanical operation. There are countless choices in the market, and choosing the right oil seal is crucial. This article aims to provide you with a comprehensive guide to...Read more -

How are the o-ring cord made or what is the oring cord Manufacturing Process ?

How are the o-ring cord made or what is the oring cord Manufacturing Process ? today we will tell you oring cord or rubber cords Manufacturing Process. The processing process of rubber sealing strips usually includes the following steps: 1. Mixing of rubber raw materials: Firstly, it is n...Read more -

The Application and Importance of Hydraulic Seals in Hydraulic Cylinders

Ningbo bodi seals co.,ltd produced all kinds of Hydraulic Seals our Hydraulic Seals with high quality . A hydraulic cylinder is a device that converts hydraulic energy into mechanical energy, typically used to push or pull objects. Hydraulic cylinders are usually composed of components...Read more -

The difference between Glyd ring and Step Seal

The difference between Glyd ring and Step Seal The main The difference between Glyd ring and Step Seal is: Glyd ring is a bi-directional sealing ring that can seal pressure in both directions. Glyd Ring The Gretel ring is composed of a rubber O-ring and a polytetrafluoroethylene ...Read more -

Method for measuring the small size of Rubber O-rings

Method for measuring the small size of Rubber O-rings as following: 1. Place the O-ring horizontally; 2. Measure the first outer diameter; 3. Measure the second outer diameter and take the average value; 4. Measure the first thickness; 5. Measure the thickness for the second time and take the ...Read more -

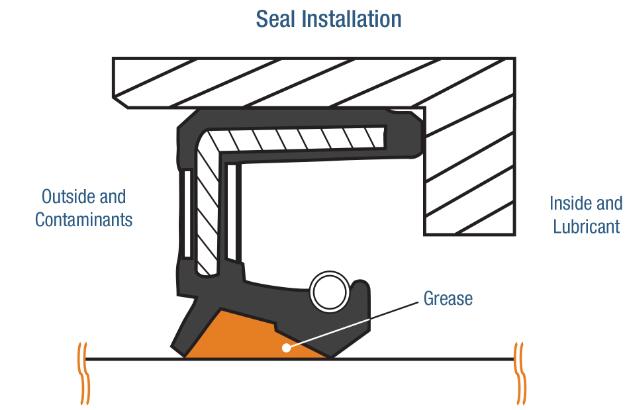

Oil Seal Installation illustrate for European and American markets

Oil Seal Installation illustrate for European and American markets When it involves a repair, you must first remove the old oil seal. To remove an oil seal, it is important to use the right tools to avoid damaging the shaft and bore. The best solution is therefore to pull out the oil seal with...Read more -

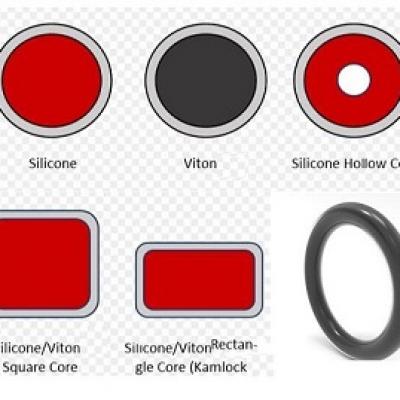

What are the application requirements for FEP/FKM FEP/VMQ ORINGS?

EP PTFE Encapsulated O-Rings combine ultimate chemical resistance of FEP PTFE with the compress ability of rubber or steel spring core. Select from the various core options to satisfy your application. FEP PTFE stiffness can require custom gland design to maximize sealin...Read more