People also ask what is the o-ring cord rubber cord

People also ask what is the o-ring cord rubber cord

O-Ring Cord (also known as o-ring strip or o-ring rope or rubber strip) is a rubber cord seal with a circular cross-section. It can be directly used on a sealing groove to prevent fluid or gas from leaking or cut the required length and use specific glue to DIY join two ends to form the needed standard o-ring. The rubber cord is usually stretch-formed, so its manufacturing time is short. It can be cut to 1-meter length or rolled into 50meter, 100-meter or longer for easy packing and transportation.

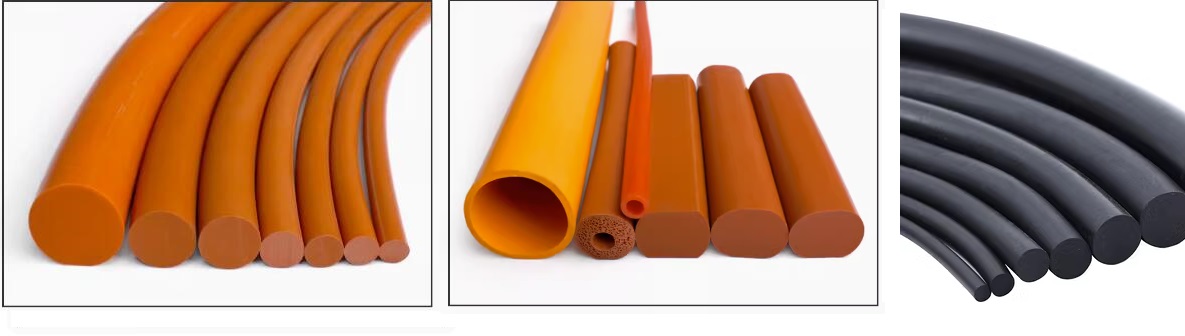

According to the cross-sectional shape, the o-ring cord can be divided into four types, namely standard, square, rectangular, and quad. The standard one is the most widely used and the most cost-effective cord, and the quad ring cord is of the best performance but very expensive.

Standard O-Ring Cord

Its profile/cross-section is circular (O-shaped) and it is the most commonly used cord stock with the lowest price.

Square O-Ring Cord

Its profile/cross-section is square (▢-shaped) and it can replace a standard cord while providing a better sealing function.

Rectangular O-Ring Cord

Its profile/cross-section is rectangular (▭-shaped) and it is used in those sealing grooves which are rectangular in shape.

Quad Ring Cord(X-ring Cord)

Its profile/cross-section is quad (X-shaped) and it can be used in both static and dynamic applications. lt alsot has a longer service life.

- O-Ring Cord Materials

-

NBR/ Nitrile O-Ring Cord–most cost-effective, used for most industries and applications.

-

Viton O-Ring Cord–higher temperature, strong chemical resistance, good performance, and higher cost.

-

Silicone O-Ring Cord–tasteless and non-toxic, used in medical and food industries, especially FDA silicone.

-

EPDM O-Ring Cord–good resistance to aging, weather, and chemical corrosion, especially used in the automobile industry.

-

Neoprene O-Ring Cord–good elastic, anti-violent twisting, resistance to abrasion and fire, with good chemical stability.

-

PTFE ORing Cord–belongs to plastic material, with high hardness, and good chemical stability, commonly used as a backup ring.

-

PU(Polyurethane)ORing Cord-belongs to plastic material ,especially suitable for dynamic loads.

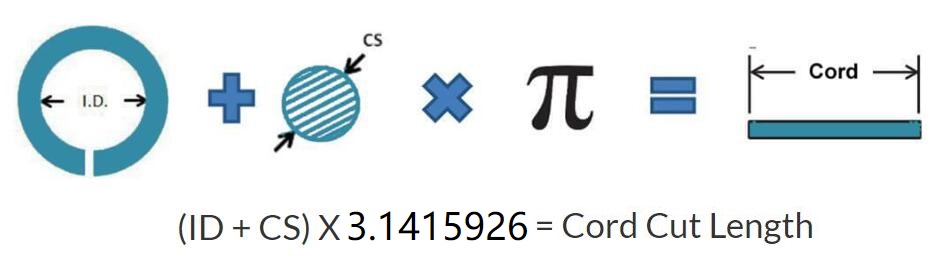

- O-Ring Cord Cut Length Calculator

You can calculate the proper cut length of the rubber cord stock extrusion with the following calculator. Please confirm the right values of the inside diameter (ID) and the profile cross-section (CS) first and then do some simple calculations.

For Example:

Using a 10mm (CS) diameter cord, the user wants to make a standard o-ring that has a 300-mm inside diameter.

The calculation to cut the length of the cord to make the needed o-ring is as follows:

300 (ID)+10 (CS)= 310

310×3.1415926= 973.89mm

The cord shall be cut to a length of 973.89 mm to make the needed o-ring.

- O-Ring Cord Size Chart & Tolerance

The size of a standard cord is measured by profile diameter. This chart shows both the imperial and metric sizes. The table also displays the o-ring cord tolerance, so that you can accurately calculate whether the cord can be suitable for your precise application. Among these sizes, the inch size is slightly different from the AS568 o-ring size, while the metric size is mainly based on china market and some overseas market. Basically, we can manufacture all of these sizes of cord at high quality, very competitive price, and very fast delivery. If some size is not listed in the table, please must contact us to discuss your customized cord. The packing of the rubber cord could be very simple or tied into a roller. Please order according to your actual needs.

| Metric O-Ring Cord Size Chart | Imperial O-Ring Cord Size Chart | ||||||

| Metric CS (mm) | Actual CS (inch) | Tolerance (mm) | Nominal CS (inch) | Actual CS (inch) | Metric CS (mm) | Tolerance (inch) | |

| 2 | 0.079 | ± 0.20 | 1/16″ | 0.07 | 1.78 | ± 0.008 | |

| 2.5 | 0.098 | ± 0.25 | 3/32″ | 0.103 | 2.62 | ± 0.010 | |

| 3 | 0.118 | ± 0.25 | 1/8″ | 0.139 | 3.53 | ± 0.014 | |

| 3.5 | 0.138 | ± 0.35 | 3/16″ | 0.21 | 5.33 | ± 0.016 | |

| 4 | 0.157 | ± 0.35 | 1/4″ | 0.275 | 6.99 | ± 0.022 | |

| 4.5 | 0.177 | ± 0.40 | 5/16″ | 0.313 | 7.95 | ± 0.022 | |

| 5 | 0.197 | ± 0.40 | 3/8″ | 0.375 | 9.53 | ± 0.022 | |

| 5.5 | 0.217 | ± 0.40 | 13/32″ | 0.406 | 10.31 | ± 0.022 | |

| 6 | 0.236 | ± 0.40 | 7/16″ | 0.437 | 11.1 | ± 0.026 | |

| 6.5 | 0.256 | ± 0.55 | 15/32″ | 0.472 | 11.99 | ± 0.026 | |

| 7 | 0.276 | ± 0.55 | 1/2″ | 0.5 | 12.7 | ± 0.026 | |

| 7.5 | 0.295 | ± 0.55 | 9/16″ | 0.562 | 14.27 | ± 0.026 | |

| 8 | 0.315 | ± 0.55 | 5/8″ | 0.625 | 15.88 | ± 0.026 | |

| 8.5 | 0.335 | ± 0.55 | 3/4″ | 0.75 | 19.05 | ± 0.033 | |

| 9 | 0.354 | ± 0.55 | 7/8″ | 0.875 | 22.23 | ± 0.033 | |

| 10 | 0.394 | ± 0.55 | 1″ | 1 | 25.4 | ± 0.039 | |

| 11 | 0.433 | ± 0.65 | 1-1/16″ | 1.062 | 26.97 | ± 0.039 | |

| 12 | 0.472 | ± 0.65 | 1-1/8″ | 1.125 | 28.58 | ± 0.039 | |

| 13 | 0.512 | ± 0.65 | 1-1/4″ | 1.25 | 31.75 | ± 0.039 | |

| 14 | 0.551 | ± 0.65 | 1-1/2″ | 1.5 | 38.1 | ± 0.039 | |

| 15 | 0.591 | ± 0.65 | |||||

| 16 | 0.63 | ± 0.65 | |||||

| 17 | 0.669 | ± 0.65 | |||||

| 18 | 0.709 | ± 0.85 | |||||

| 19 | 0.748 | ± 0.85 | |||||

| 20 | 0.787 | ± 0.85 | |||||

| 21 | 0.827 | ± 0.85 | |||||

| 22 | 0.866 | ± 0.85 | |||||

| 23 | 0.906 | ± 0.85 | |||||

| 24 | 0.945 | ± 0.85 | |||||

| 25 | 0.984 | ± 0.10 | |||||

| 26 | 1.024 | ± 0.10 | |||||

| 27 | 1.063 | ± 0.10 | |||||

| 28 | 1.102 | ± 0.10 | |||||

| 29 | 1.142 | ± 0.10 | |||||

| 30 | 1.181 | ± 0.10 | |||||

- The field of use the rubber cords/ O-Ring Cord

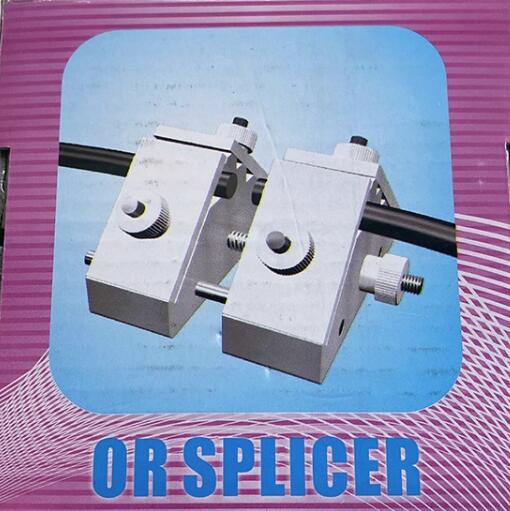

Finally, we introduce an O-ring connection device named OR SPLICER to you ,the photo as following :

Price: Offer maximum discounts based on good quality in advance

Payment: Flexible and Communicable Popular credit sales at present

Quality: Any quality issues within 1 year can be returned or exchanged

Delivery: For small order within 7days , for big order can be discussed

Stock : AS568 all sizes & Metric O-Ring Cord From diameter 1mm to 100mm

Service Concept: Sincere Understanding best support Respect partnerships like family